Gap Identification in SAP ERP Implementation: A Key to Project Success

Posted on February 10, 2025 by Laeeq Siddique

Authored by Mr. Laeeq Siddique — Leading SAP S/4HANA Innovation & Strategy

1. Introduction

Implementing SAP ERP is a transformative step for any organization, but its success hinges on one critical factor: SAP ERP gap identification. This refers to recognizing the misalignments between your existing business processes and the standard functionalities provided by SAP. Without identifying these gaps early, organizations face costly delays, resource inefficiencies, and implementation failure. Therefore, SAP ERP gap identification is not just a best practice—it’s a strategic imperative for successful deployment.

Therefore, SAP ERP gap identification is not just a best practice—it’s a strategic imperative for successful deployment. If you’re looking to understand some of the challenges that could affect your SAP ERP system, check out our blog Why Would You NOT Recommend SAP as an ERP? for a deeper dive into potential pitfalls businesses may encounter.

2. Understanding SAP ERP Gap Identification

What exactly are these ‘gaps’ in an SAP ERP implementation? They refer to disparities or differences between the functionalities provided by the SAP system and the requirements of the business processes it’s intended to support. Gaps can be related to business processes, functionality, or technical aspects.

A business-process related gap might exist if your organization follows a unique order-processing workflow that standard SAP ERP does not support. A functional gap could arise if SAP lacks specific features necessary for your business. A technical gap might be present if SAP isn’t compatible with your existing IT infrastructure or doesn’t support the desired level of customization.

If you’re curious about how these gaps could cause issues during your implementation, take a look at our blog Why Would You NOT Recommend SAP as an ERP? for more insights on how SAP might not fit every business perfectly.

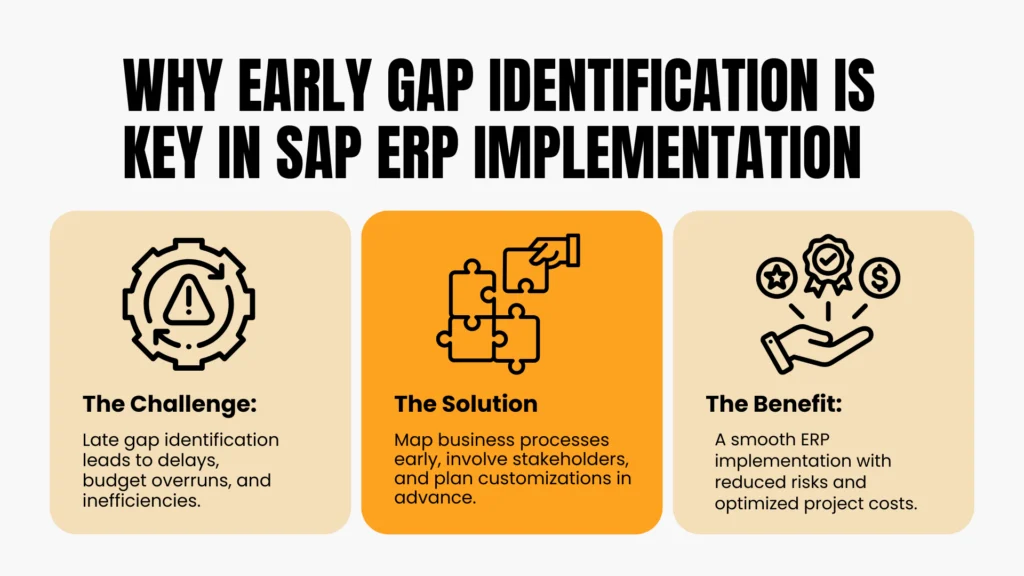

3. Risks of Poor SAP ERP Gap Identification

Failing to identify SAP ERP gaps early can damage your project. If found during or after implementation, gaps disrupt schedules. Teams must rework plans or redesign workflows, causing delays and missed deadlines.

Budget overruns often follow late gap identification. Extra development or hardware expenses increase total costs. Reallocating resources or hiring consultants adds more strain to the budget.

Training is also affected. Late changes force teams to rewrite training materials and reschedule sessions. This results in more cost and delays. Identifying gaps at the start helps avoid these issues completely.

To understand what kind of challenges you might face after implementation—especially with user experience—explore our blog on 5 Major Hurdles and Solutions in Adopting SAP Fiori after S/4HANA Implementation.

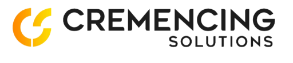

4. Why Missed SAP ERP Gaps Aren’t Always Developer Faults

Many people blame the development team when an SAP ERP implementation fails. They assume poor coding caused the issues. But in most cases, the real cause is poor SAP ERP gap identification.

Developers can only solve problems they know about. If no one identifies business process gaps early, the team builds a system that doesn’t meet actual needs. Even if the solution works technically, it won’t support your goals.

The issue is not the developers—it’s the missing information. Late discovery of gaps leads to misaligned outcomes, even with strong execution.

5. The Importance of Early Gap Identification

Early SAP ERP gap identification prevents delays, rework, and unnecessary costs. When teams understand gaps at the start, they can plan better, budget accurately, and prepare effective training materials.

Developers can begin creating custom solutions early, ensuring the system fits your actual needs. From a project management view, early gap discovery gives more control over scope and delivery.

You can estimate costs and timelines realistically. Most importantly, you reduce risks and ensure your SAP system integrates smoothly into existing operations.

6. Effective Strategies for SAP ERP Gap Identification

To identify gaps early in your SAP ERP implementation, a thorough understanding of your existing business processes is required. This can be achieved through a meticulous business process mapping exercise, which should ideally be the first step in any ERP implementation project.

Involving key stakeholders from various business units in this exercise can ensure a holistic view of all business processes, helping you uncover any hidden requirements or unique workflows that could otherwise become gaps.

Working closely with your SAP partner or consultant during this phase can also be beneficial. They can help compare your current business processes with standard SAP processes, allowing you to identify any potential gaps and discuss the best ways to address them.

7. Development Team’s Role in Addressing SAP ERP Gaps

Once the gaps are identified, your development team plays a crucial role in creating custom solutions that fill these gaps. Their knowledge of SAP’s technical capabilities can help devise effective solutions, whether it’s modifying existing SAP functionalities or developing custom applications within the SAP ecosystem.

However, it’s important to remember that their success depends largely on how well the gaps are identified and communicated to them. Accurate and timely communication of gaps can enable the development team to work effectively, ensuring a smooth SAP ERP implementation that meets the business’s unique needs.

8. Conclusion: Prevention is Better Than Cure

In conclusion, the success of an SAP ERP implementation is a product of a collective effort, beginning with meticulous early-stage planning to identify gaps between your business processes and the standard SAP ERP system functionalities.

When these gaps are identified and communicated early, all teams involved—development, management, end-users—can work in harmony to devise effective solutions. This joint effort can lead to a smoother, more efficient ERP implementation that aligns with your business needs and drives value.

A people-first approach can further enhance ERP success. Making Employees Feel Safe and Valued Amid ERP Implementation

The key message here? Success can be achieved, but it’s a team sport. And in this game, recognizing and addressing gaps early on is our star player. As the adage goes, a stitch in time saves nine, and in the context of ERP implementation, prevention is indeed better than cure.